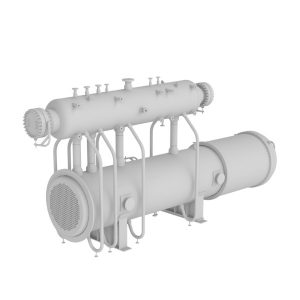

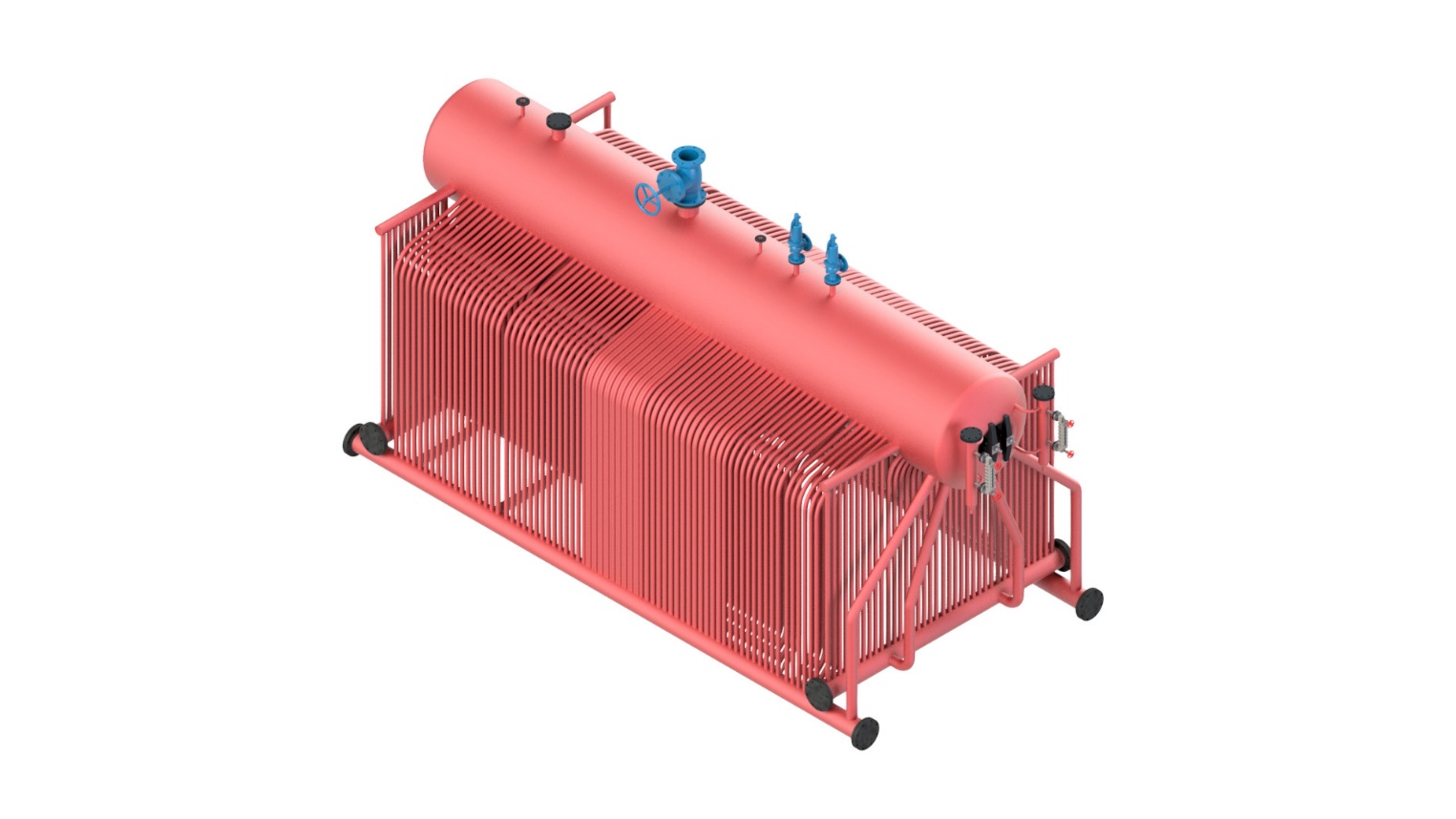

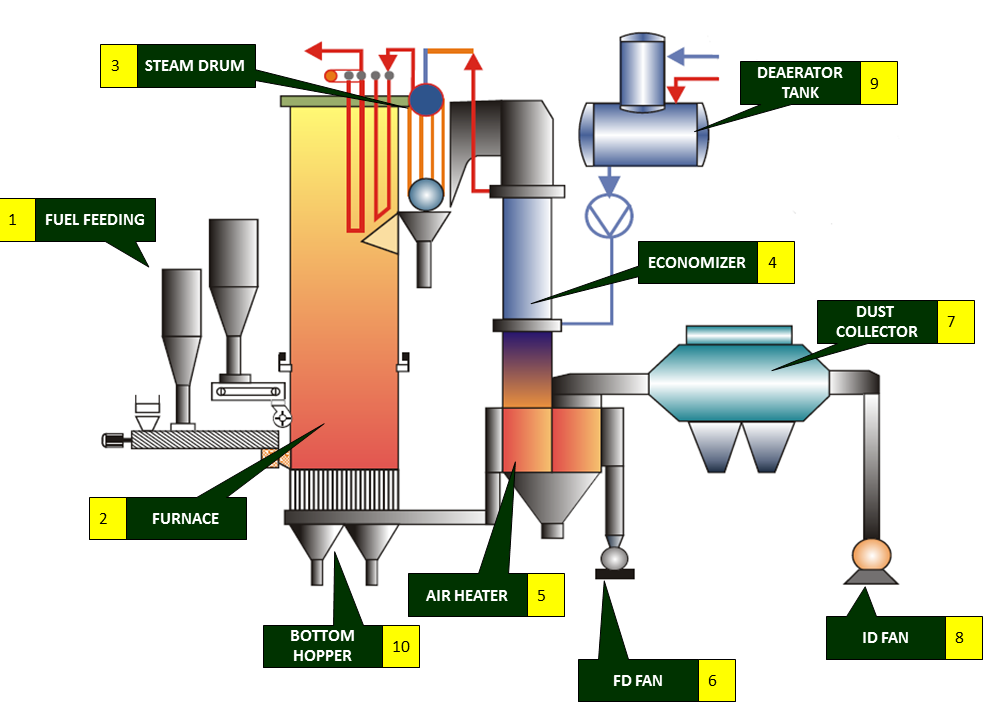

In a water tube boiler, boiler feed water flows through the tubes and enters the boiler drum. The circulated water is heated by the combustion gases and converted into steam at the vapor space in the drum. These boilers are selected when the steam demand as well as steam pressure requirements are high as in the case of process cum power boiler /

power boilers.

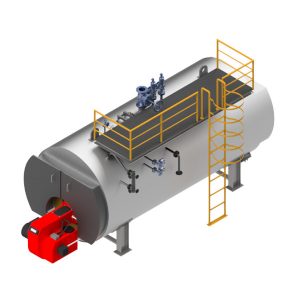

The features of packaged boilers are:

- Forced, induced and balanced draft provisions help to improve combustion efficiency.

- Less tolerance for water quality calls for water treatment plant.

- Higher thermal efficiency levels are possible

Particular Water Tube Boiler

Fluidized Bed Combustion (FBC) Boiler

Fluidized bed combustion (FBC) has emerged as a viable alternative and has significant advantages over a conventional firing system and offers multiple benefits – compact boiler design, fuel flexibility, higher combustion efficiency and reduced emission of noxious pollutants such as SOx and NOx. The fuels burnt in these boilers include coal, rice husk, saw dust, bagasse & other agricultural wastes.

The Fluidized Bed Combustion (FBC) process is the process where the fuel particles are suspended in a hot, bubbling fluidity bed of ash and other particulate materials (sand, limestone, etc.) through which jets of air are blown to provide the oxygen required for combustion or gasification. The resultant fast and intimate mixing of gas and solids promotes rapid heat transfer and chemical reactions within the bed.

The fluidized bed boilers have a wide capacity range- 0.5 T/hr to over 100 T/hr.

Most operational boiler of this type is of the Atmospheric Fluidized Bed Combustion (AFBC)

Chain Grate or Travelling Grate Boiler

Coal is fed onto one end of a moving steel grate. As the grate moves along the length of the furnace, the coal burns before dropping off at the end as ash. Some degree of skill is required, particularly when setting up

the grate, air dampers and baffles, to ensure clean combustion leaving the minimum of unburnt carbon in the ash.

The coal-feed hopper runs along the entire coal-feed end of the furnace. A coal gate is used to control the rate at which coal is fed into the furnace by controlling the thickness of the fuel bed. Coal must be uniform in size as large lumps will not burn out completely by the time they reach the end of the grate.

With Tebmit’s design, chain grate boiler is similar to the automatic and stable for small capacity in range 3TPH to 40TPH.

This boiler proved via the multi fuels flexibility as separated or mixed even with the different sizes.

Tiếng Việt

Tiếng Việt