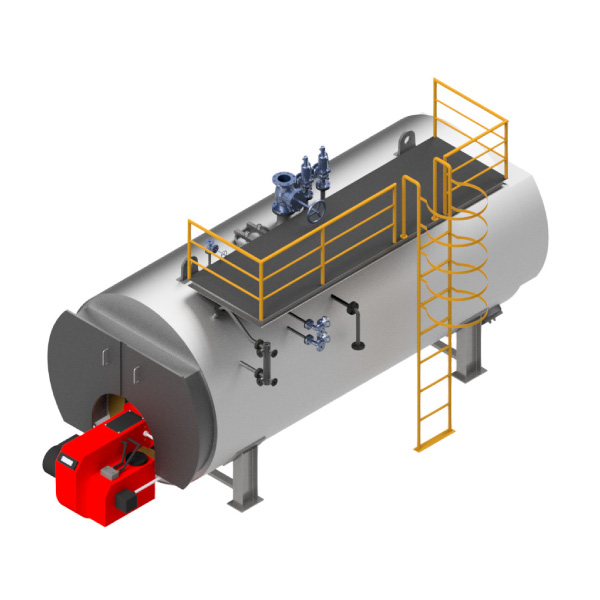

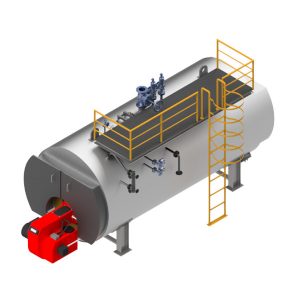

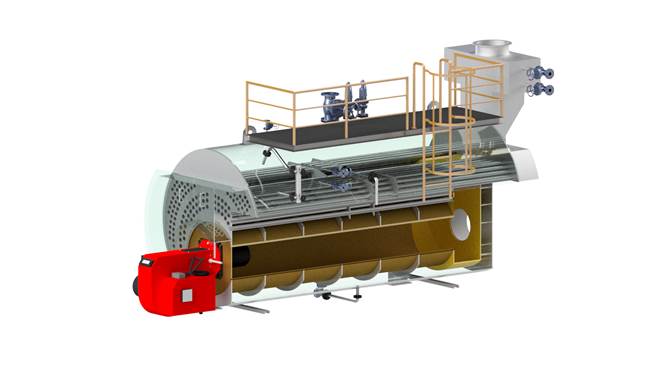

In a fire tube boiler, hot gases pass through the tubes and boiler feed water in the shell side is converted into steam. Fire tube boilers are generally used for relatively small steam capacities and low to medium steam pressures. As a guideline, fire tube boilers are competitive for steam rates up to 12,000 kg/hour and pressures up to 18 kg/cm2. Fire tube boilers are available for operation with oil, gas or solid fuels.

The features of packaged boilers are:

- Small combustion space and high heat release rate resulting in faster evaporation.

- Large number of small diameter tubes leading to good convective heat transfer.

- Higher thermal efficiency levels compared with other boilers if it is equipped forced or induced draft systems resulting in good combustion efficiency.

- Number of passes resulting in better overall heat transfer.

These boilers are classified based on the number of passes – the number of times the hot combustion gases pass through the boiler. The combustion chamber is taken, as the first pass after which there may be one, two or three sets of fire-tubes. The most common boiler of this class is a three-pass unit

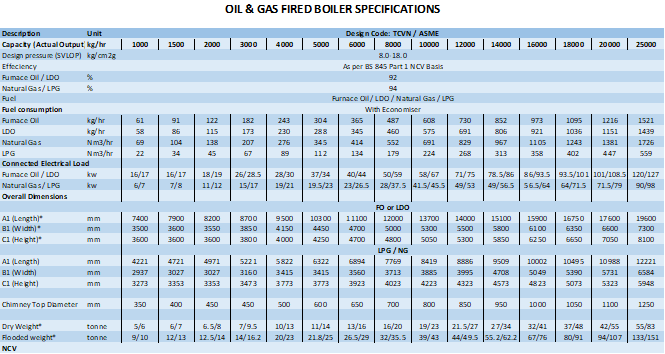

Specifications

Tiếng Việt

Tiếng Việt